Best Technology ┃ Maximise Efficiency ┃ Minimise Cost

Process and Functional Safety

Process and machine safety is fundamental to control system design. CXC assess plant hazards and operations to determine a safety system architecture that meets your needs.

LOPA analysis identifies the layers of protection, remaining gaps and necessary safety instrumented function, SIF.

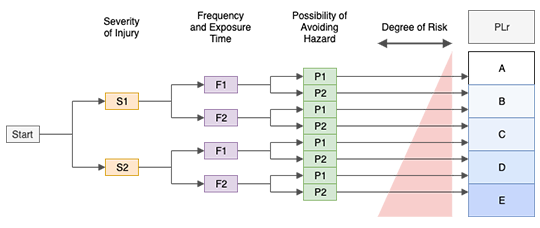

Risk Assessments

Safety Instrumented System Design and SIL Verification (Gap Closure)

SIS are designed to utilise both hardwired safety relays and fail-safe electronic systems such as safety PLCs, fail-safe drives and fail-safe communications.

Failsafe and highly fault tolerant design can be achieved to meet SIL3 utilising dual sensors and devices.

Process safety and SIS are designed, built, installed, and commissioned to IEC 61508 and IEC 61511 and Machinery Safety to IEC/EN 62061 and ISO 13849 solutions to close all LOPA gaps.

Hazardous Areas

Dangerous Substances and Explosive Atmospheres Regulations 2002 (DSEAR) are in place to ensure the safe control of flammable vapours and dusts.

CX Controls design, build and commission systems to meet the ATEX directive 99/92/EC requirements.

Please contact us for a free quotation and tell us all about your business needs

Thank you for enquiring about CX Controls’ services, please fill in the form and we will be in touch shortly.

Station Road, Mochdre,

Conwy, LL28 5EF, UK

---------

International House,

61 Mosley Street,

Manchester, M2 3HZ, UK